Laser Chiller for Cooling Laser Tube Cutting Machine

Laser Chiller for Cooling Laser Tube Cutting Machine

Blog Article

Metal pipes are widely used in daily life, particularly in sectors such as furniture, construction, gas, bathrooms, windows and doors, and plumbing, where there is a high demand for pipe cutting. In terms of efficiency, cutting a section of pipe with an abrasive wheel takes 15-20 seconds, whereas laser cutting takes just 1.5 seconds, improving production efficiency by over ten times.

Additionally, laser cutting does not require consumable materials, operates at a high level of automation, and can work continuously, whereas abrasive cutting requires manual operation. In terms of cost-effectiveness, laser cutting is superior. This is why laser pipe cutting quickly replaced abrasive cutting, and today, laser pipe cutting machines are widely used across all pipe-related industries.

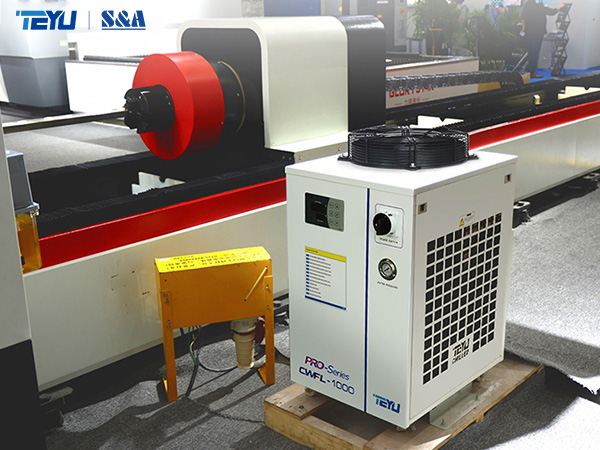

TEYU fiber laser chiller CWFL-1000 features dual cooling circuits, allowing for independent cooling of the laser and the optics. This ensures precision and cutting quality during laser tube cutting operations. It also incorporates multiple alarm protection functions to further protect the equipment and production safety.

Source: https://www.teyuchiller.com/teyu-laser-chiller-cwfl-1000-for-cooling-laser-tube-cutting-machine